Case

Sandvik Prism

Awardwinning production tool for CNC-machines

We made this using:

Redux

React

App development & frontend

Background

Sandvik manufactures tool systems and machinery for industrial and mining companies. Rhyme and Sandviks cooperation began when Sandvik spotted an opening in the market for providing small and mid-sized workshops the opportunity to increase the efficiency of their CNC machinery by the use of a digital tool. Computer Numerical Control (CNC) is the automated control of machining tools, e.g. drills, boring tools, lathes and 3D printers by the use of a computer. A CNC machine can thus process a piece of material to meet specifications by following a coded programmed instruction without a manual operator. Sandvik performed market research resulting in the decision to create a mobile programming tool instead of a stationary option.

Challenge

Award-winning production control tool for CNC machinery. Sandvik manufactures tool systems and machinery for industrial and mining companies. Rhyme and Sandviks cooperation began when Sandvik spotted an opening in the market for providing small and mid-sized workshops the opportunity to increase the efficiency of their CNC machinery by the use of a digital tool. Computer Numerical Control is the automated control of machining tools, e.g. drills, boring tools, lathes and 3D printers by the use of a computer. A CNC machine can thus process a piece of material to meet specifications by following a coded programmed instruction without a manual operator. Sandvik performed market research resulting in the decision to create a mobile programming tool instead of a stationary option.

Solution

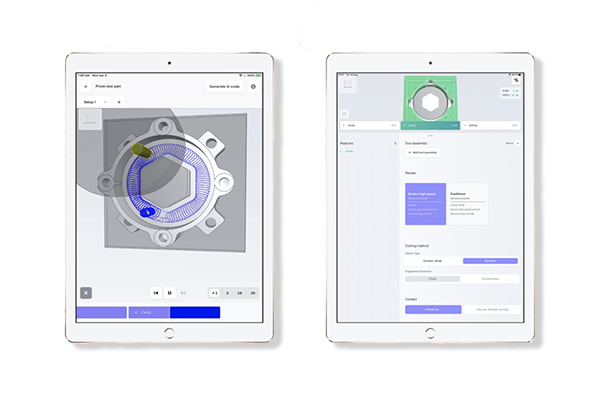

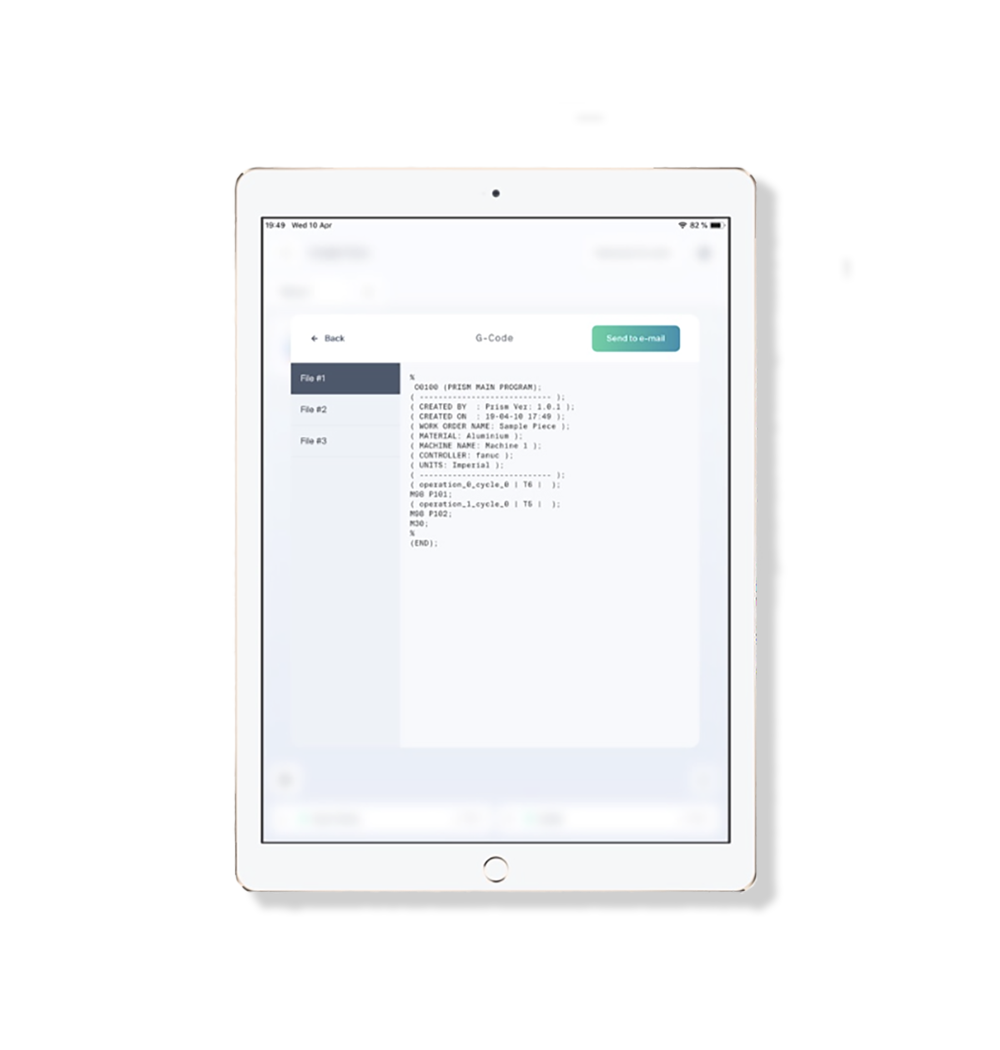

The resulting product, called Prism, is the first CAM (Computer-Aided Manufacturing) application for iPad. It manages the entire cycle of machining — programming, simulation, post-processing and export to CNC-code. The real-time feedback of the 3D interface allows nearly anyone to understand CNC programming. Prism also opens a new era of smarter manufacturing by being the first product to offer Cookbooks for CNC machines, which allows machining experts to package and monetise their expertise, making the machining know-how of the industry available to anyone. The final marketed product is an integrated solution that reduces programming time by up to 94%.

Results

The final marketed product is an integrated solution that has strengthened Sandvik’s competitive position within machining solutions by:

- Reducing programming time by up to 94%

- Increase the utilisation rate of machines

- Minimize human error

- Reducing scrap material

- Enabling knowledge-sharing from experts